Purified Water Production Facility

Many African countries have top-quality, drinkable water resources. The team of Baobabtrees has supported enterprises in Ethiopia, Kenya and South Africa to turn this gift of nature into top-quality commodities that generate considerable profit for its investors. We understand the purified water processing needs and challenges of African countries. Our niche is to materialise the African needs into accurate solutions.

We are experienced in supplying complete production facilities for purified water (from the municipal water source, natural spring water and borehole water source). We assisted Water of Life brand owner Mr Mali from South Africa in planning his exciting new purifying and bottling line to supply bottled water around the Nelson Mandela Bay region.

On the front end, we provide CE certified water treatment system (standard flow rates vary from 6 tons/hour to 12 tons/hour on a single line; it can be customised beyond this range). Between the raw and purified water tank, there is a comprehensive filter and sterilisation solution package to ensure the water quality before bottling. This system includes:

We specialise in the system for effectively eliminating the traces of typhoid, diphtheria and cholera. The system engineering is also highly customisable for adapting to the production site’s actual resource context and conditions.

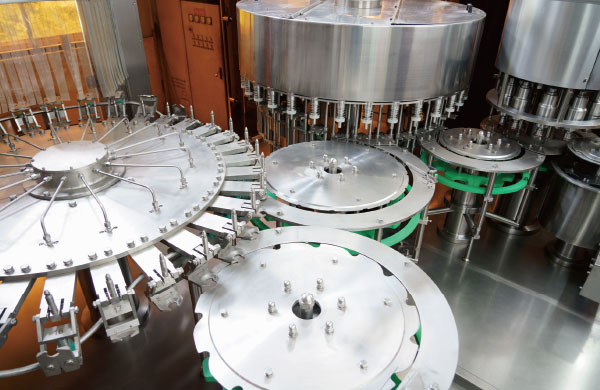

For the back-end processing, we have successfully introduced fully- automated bottling lines with 8000 BpH, 10000 BPH and up to 18000 BPH capacities. We are experienced in providing bottling solutions for 500ml, 1000ml, 1500ml and 2000ml. We can also create solutions for 5000 ml with customers’ demands.

The bottling line starts with the automatic bottle blowing system, air-conveyed to the automatic filling machine (with cap elevator and online cap steriliser), followed by the light checking section, blow drying, sleeve labelling and label shrinking, laser print/marking and fully automated PE film packing.

With a reasonable amount of investment, we have helped the SME water workshop to transform into a water processing plant with full technical support and management strategy guidance (i.e. workflow design, work posts outlining, skill development targets). The solution from Baobabtrees is not only about facility engineering and procurement but also about assisting entrepreneurs to be operationally ready.